Bleaching

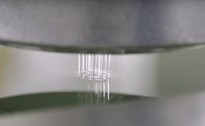

MC-mixers: Two CRS Engineering mixing reactors are capable of handling 200 g batches of pulp at consistencies of 10-15 %. The first reactor is of stainless steel construction and is particularly suited for alkaline treatments and ozone bleaching. The reactor is equipped with two gas dosage systems: one for oxygen and one for ozone. The reactor is connected to an ozone generator and equipment for collecting, pressurizing and feeding ozone gas into the reactor. The second reactor is constructed of titanium and can be used for bleaching with chlorine chemicals. Both of the MC bleaching reactors consist of a reactor vessel, fluidization mixer and reactor lid.

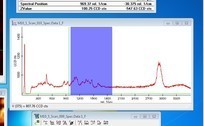

Chlorine dioxide generation unit: (DENSO): The DENSO chlorine dioxide generator is designed for onsite preparation of chlorine dioxide, its generation principle is based on the reduction of chlorate with acid. Chlorine dioxide required for bleaching purposes is prepared with this generator which can achieve a concentration of over 20 g/L active chlorine. The reaction does not generate Cl2-gas as a by-product.

Ozone generation unit: The ozone generator has capacity is about 10 g O3/h with 150 L/h gas flow.

Water bath unit: Pulp bleaching under 100 °C in small scale in plastic bags under atmospheric pressure. Most common bleaching methods are peroxide and chlorine dioxide bleaching stages.