Printability

Laboratory printability tester: The Universal Testprinter complies with all international standards: Dry pick, wet pick, wet repellence, mileage, colour measurement, trapping, back trap mottle and automated set off. The instrument is also capable of simulating all common printing techniques: Offset, flexography, gravure and letterpress.

Ink emulsifier tester: Duke tester

Ink Tack: Tack-o-scope

Print tack (Printack): The Printack investigates the setting of inks on coated substrates.

Mechanical properties

- Abrasion resistance (PATRA and a linear rubbing tester)

Optical properties

- Optical density (Vipdens 2000 densitometer),

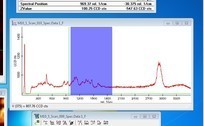

- Spectrofotometric measurements (GretagMacBeth-spectroscan)

- Gloss (Vipgloss gloss meter),

- Colour and print quality parameter values (QEA image analyzer).

Visual testing (Minimatcher-MM4e): Viewing station.

Printing simulation (Sinapse Print Solutions): heatset web offset and packaging flexo simulation programs.

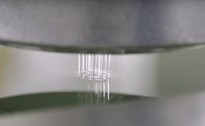

Dimatix Materials Printer DMP-2831 (Fujifilm Dimatix, Santa Clara, USA) is a piezo-electric inkjet printer intended for laboratory research and development work and prototyping in the field of functional printing. It allows user to experiment and observe jettability and printability of custom inks, with a wide range of adjustable parameters. At the Department of Forest Products Technology DMP-2831 has been used for example for printing conductive nano-silver suspensions, polyelectrolyte solutions, hydrophobising inks and photovoltaic materials on a variety of substrates.